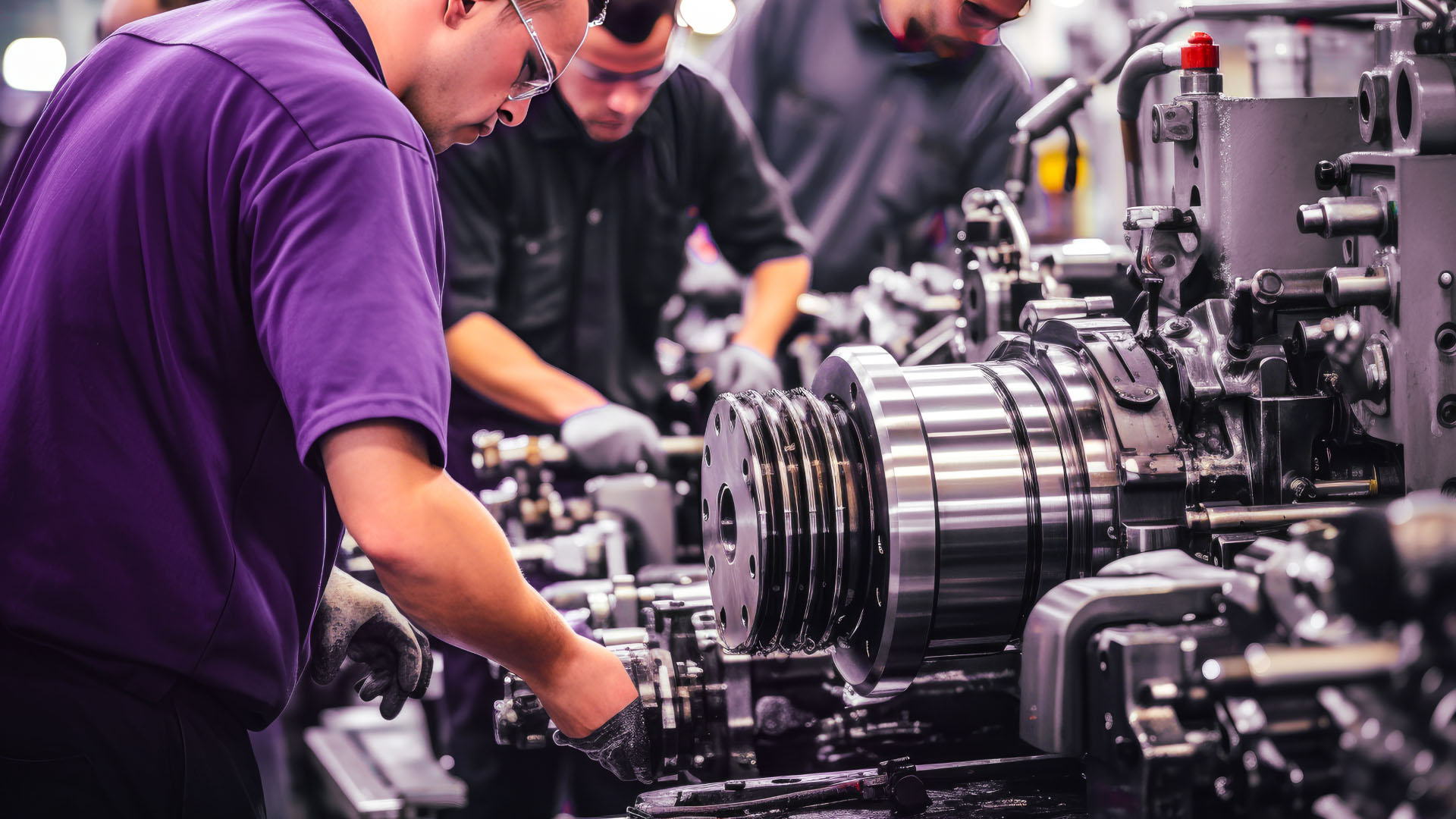

Optimize your production and assembly – fast and flexible

Time is money in production. You need quickly available, customized fixtures that optimize your production and assembly processes.

Standard solutions don’t fit your processes?

Your assembly processes are time-consuming and error-prone because standardized fixtures do not fit your components optimally or are missing entirely.

Your employees deserve better tools?

Your employees complain about inefficient workflows because universal fixtures are not designed or adaptable to your specific assembly processes.

Our Solution:

We support you with:

- Customized production and assembly fixtures

- Improved workplace ergonomics

- Increased repeatability with reduced error potential

- Quickly available spare parts

Here’s how we proceed:

- Analysis of your assembly processes (5S method, value stream analysis, MTM analysis or workplace analysis, etc.)

- Identification of optimization potential

- Development of customized solutions and tools that integrate optimally into your production system

- Fast manufacturing and implementation

- Continuous improvement in the spirit of CIP and Kaizen

Next level engineering for your industry

Your path to 3D printing

01

Free first consultation

02

Potential analysis

03

Pilot project

04

Implementation